125+ Plants in

55+ Cities

Our Incredible Journey

Tech Enabled

RMC Player

1800+

Strong Team

10000+ Customers

840+

Transit Mixers

3000+ Daily Dispatches

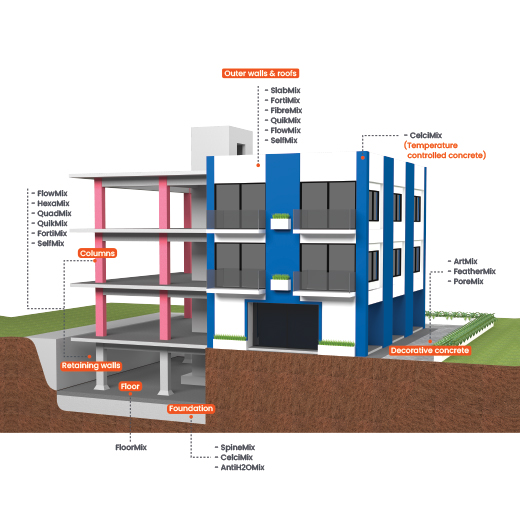

Value-Added Concrete Portfolio

Key Projects

Trust of numerous clients earned over several prestigious projects

Key Infrastructure Projects

Mumbai Metro

Delhi Metro

Kochi Metro

NHAI Projects

Chennai Metro

Delhi-Meerut RRTS

Navi Mumbai Airport

Kempegowda Airport

Adani LNG Terminal

Key Real Estate Projects

Amazon Data Center

Apple Assembling Unit

DRDO Data Center

Key Partners

Our Presence

125+ plants in 55+ cities

Customised Product Offerings

Value Added Products for Mid - Highrise segment

Testimonials

FAQs

As per Bureau of IS 4926:2003 , Ready Mixed Concrete (RMC)- Code of Practice, RMC can be termed as `Concrete mixed in a stationary mixer in a central batching and/or mixing plant or in a truck-mixer. It is supplied in fresh condition to the purchaser at site. It is a premixed product, designed for specific requirements and ready to use at site. RMC is made by a systematic method and transported to project sites while maintaining the desired fresh properties of concrete.

There are different Ready Mix Concrete Solutions offered on the basis of Site Problems & requirement.

Following are the list of Product (different types of RMC) by INFRA.MARKET CONCRETE:-

- ArtMix – Decorative and coloured Concrete Solution

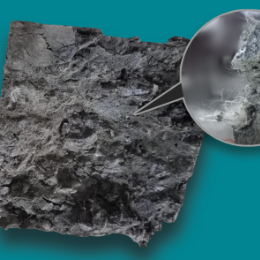

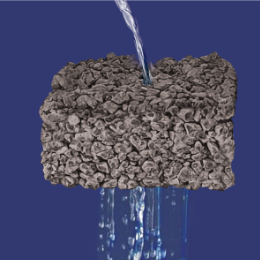

- PoreMix – Pervious Concrete

- HexaMix – 6 Hrs Retention Concrete

- QuadMix – 4 Hrs Retention Concrete

- SelfMix – Self Compacting Concrete

- FibreMix – Fiber Reinforced Concrete

- EnviroMix – Low Carbon Concrete

- QuikMix – High Early Strength Concrete

- BagMix - Dry and BagMix - Wet – Bag Concrete

- FeatherMix – Light Weight Concrete

- FortiMix– High Strength Concrete M60 Above

- CelciMix – Temperature Controlled Concrete

RMC is used as a building material in construction projects for commercial, residential, or infrastructure development purposes as it helps to achieve faster construction and enhances productivity.

RMC is generally made from OPC (Ordinary Portland Cement), PPC (Portland Pozzolana Cement) and PSC (Portland Slag Cement). Usage of the kind of cement is almost always governed by customer requirement.

The key benefits of using RMC are as follows:

- RMC can serve a wide area including remote locations i.e. mass production is possible.

- Better quality of concrete is produced.

- Elimination of storage space for basic materials at site.

- Wastage of Basic materials is avoided.

- Saves labor costs

- Water-cement Ratio is maintained.

- Time required is greatly reduced.

Infra.Market is currently the fastest growing concrete player with 80+ plants in 50+ cities. Our wide product range coupled with technical expertise, excellent product quality and customer friendly service make us the trusted partner for every project. We are a trusted partner for over 500 projects providing on-time delivery and transparency with our tech enabled service.

Download the brochure for more information